Customized:

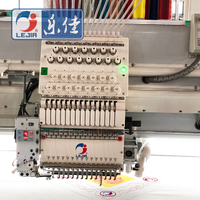

1.Head Distance:500 mm (Customized, 55/82.5/110/125/165/220/240/250/300/330/ 350/ 400, etc.)

2.Embroidery Area:X1000Y1000mm (Customized, X axis depends on the head distance, single/double/multiple alternate available, Y axis 450/500/680/750/800/900/ 1000/1200/1300/1500/1800 optional or customized )

3.Stitch Length/ Memory Capacity 0.1-12.7mm/1 billio:380V (220/380V) Power Input: 380 V (220/380V optional)

4.Auto head selection: Yes (Customized)

5.Computer: DAHAO D56

6.Main Motor: 2.3KW DAHAO servo motor

7.Frame Motor: X1Y1*1.5KW DAHAO servo motor

8.Frame Drive/Belt: X3Y5+1 linear drive/original Italy belt(Original and domestic belt optional)

9.Trimming Option: 110 stepping motor trimming

10.Color Change Option: Screw Rod(SR) Color Change(cam color change optional)

11.Upper Thread Holding: new high performance solenoid upper thread holding device

12.Tension Base: new tension base designed by Lejia

13.Head Structure: Double cam double lever structure, press foot and needle bar drive independently (normal head/single cam double lever/double cam double lever optional according to needs)

14.Jump mode: motor controlled(solenoid and motor optional)

15.Rotary Hook:original Koben rotary hook 1.6 times(Koben/Hirose/K branch optional, 1.0/1.6/2.0 times optional)

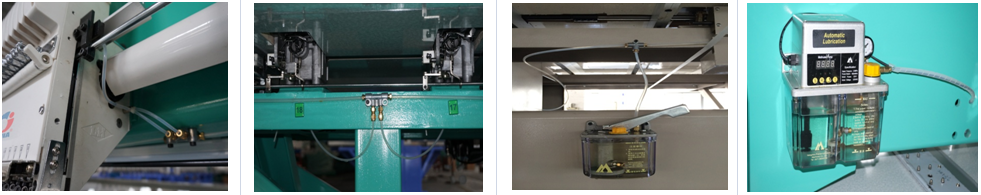

16.Oiling system: Automatic oiling system

17.Languages: Chinese, English, Spanish, Turkish, Russian, French, Portuguese, Arabic and Thai

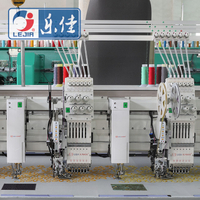

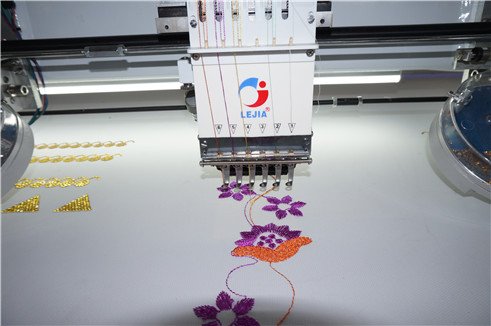

Applications:

Mainly used in fashion design, apparel fabrics, upscale wall covering, curtains, screens, water-soluble lace, children's toys, home accessories, arts and crafts and other fields.

The main product features:

1.New user friendly control system and upgraded X/Y motion and cutting system improves stitching quality and feasibility, while minimizing electric noise and maintenance.

2.Full closed loop servo motor controlled X/Y driving system, plus Germany made timing belt and jumbo bearing, assures high precision of finest stitching. Latest linear guide rail(central rod)by extra wide base and jumbo bearings make the motion in X/Y lighter and smoother, but less maintenance.

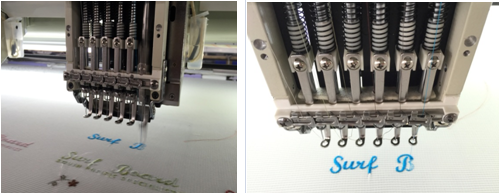

3.Unique innovative “SD” stitching arm with multiple levers and coupling by oiling-free bearing.It largely enhances the life span of driving cam for presser foot, meanwhile reaching maximum ultra high speed of 1350 SPM.

4.New designed tension base brings more smooth feeding, but less shaking of thread;thus, stitching is flat and shiny with minimum thread breakage, even on tough metallic thread.

5.New chassis applies super strong steel and sold welding techniques. Secured precision and strength minimize the vibration and thread breakage.

6.Extra strong aluminum made pantograph makes no distortion by fabric stretching force. No harm to fabric by new clamping structure.

7.Precise motor controlled jumping mode is faster, quieter, more steady, and much less maintenance

8.New designed upper thread holding system keeps thread on working status after frequent cutting and increases the productivity largely.

9.New closed loop SR(screw rod)color change system is faster, more precise and steady than ever. More efficiency, but less maintenance.

10.New closed loop powerful motor cutting system is more precise, steady, and suitable for frequent cutting, even all day and night.

11.Optional controllable oiling system(timer type is available)guarantees lubrication on parts on head and hook, and safeguards the life of parts, minimizing the down time of maintenance.

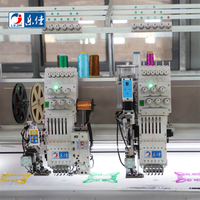

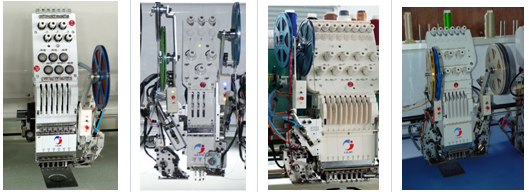

12.Optional additional features and devices such as boring, sequin, twin sequin,easy cording, lock stitch chenille, beads, laser cutting and thermal cutting make the embroidery more beautiful and add the value of the embroidery greatly.